Having a power outage due to flooding can be a frustrating experience, especially if your generator won’t start. While generators are designed to withstand harsh weather conditions, flooding can cause serious damage to these machines. Not knowing the reason behind why your flooded generator won’t start can be perplexing, but don’t worry, we’ve got you covered! In this article, we’ll provide you with some troubleshooting tips to help you identify the issue and get your generator up and running again.

So, strap in and let’s dive into the world of flooded generator troubleshooting!

Check the Fuel System

If you’re having trouble starting up your generator, you might have a flooded engine. One of the first things you should check is the fuel system. Make sure you have enough fuel and that it’s clean and free of debris.

A clogged fuel line or filter can prevent the engine from getting the fuel it needs to function properly. You should also check the carburetor and make sure it’s clean and working correctly. If the carburetor is clogged or has a dirty jet, it can cause the engine to flood.

In that case, you might need to take it apart and clean it thoroughly or consider replacing it. Another potential issue is the fuel pump, which can fail and prevent fuel from getting to the engine. In any case, checking your fuel system is a good starting point when troubleshooting a flooded generator that won’t start.

Inspect Fuel Tank

When it comes to maintaining your car, it’s important not to overlook the fuel system. A key aspect of this system is the fuel tank, which should be inspected regularly to ensure it’s functioning properly. Whether you have a gas or diesel vehicle, there are a few things to look out for when checking your fuel tank.

First, it’s important to check for any cracks or leaks in the tank, which can cause fuel to escape and potentially lead to a fire. You should also make sure that the tank is securely fastened and that all fuel lines and connections are tight and leak-free. Additionally, it’s a good idea to inspect the fuel cap for any signs of damage or wear, as a faulty cap can lead to fuel evaporation and decreased fuel efficiency.

By taking the time to check your fuel tank regularly, you can ensure that your car is running smoothly and avoid any potential safety hazards on the road.

Check Fuel Lines

When it comes to maintaining your vehicle, one crucial area to inspect is the fuel system. Checking the fuel lines is a critical step that should not be overlooked. Over time, fuel lines can become clogged or worn, leading to leaks or fuel starvation.

Inspecting the fuel lines regularly will help detect any potential issues and ensure that fuel is flowing smoothly to the engine. It’s important to look for cracks, leaks, or signs of wear and tear. If you notice any of these issues, it’s best to replace the fuel lines to prevent any further damage.

Remember that maintaining a healthy fuel system is not only crucial for your vehicle’s performance but also for your safety on the road. So, next time you’re checking under the hood, make sure to inspect your fuel lines thoroughly to keep your ride running smoothly.

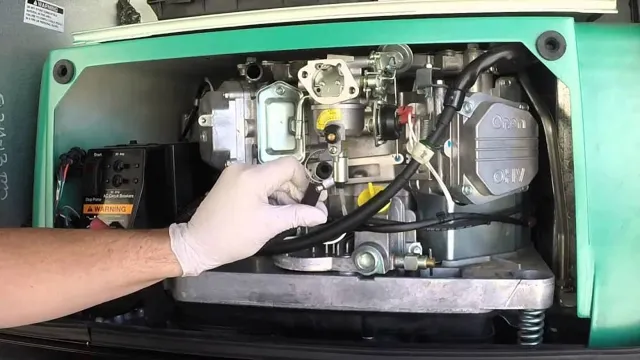

Examine Carburetor

Carburetor One crucial aspect of maintaining a vehicle is inspecting its fuel system. The carburetor, which is an essential component of the fuel system, must be examined regularly. As time goes by, the carburetor becomes clogged with dirt and debris, reducing its efficacy.

A clogged carburetor can even cause engine failure, and that’s never a good thing. To avoid such scenarios, it is crucial to inspect the carburetor for signs of clogs and addressing these issues immediately. When examining the carburetor, look for deposits of dirt, rust, and other debris that may be clogging it.

A carburetor inspection may also provide insight into whether the fuel system is functioning properly. So if your vehicle is running rough or experiencing poor fuel economy, a carburetor inspection should be on your to-do list. Here’s a pro tip: make it a habit to clean your carburetor regularly to keep it running at peak efficiency.

By doing so, you’re reducing the risk of engine failure and extending the life of your vehicle’s engine.

Inspect the Ignition System

If your generator won’t start after being flooded, it could be an issue with the ignition system. The key to start a flooded generator engine is to remove all the excess fuel from the combustion chamber. The ignition system sends an electric spark to the spark plug, which ignites the fuel in the engine.

Check the spark plug and ensure that it is not fouled or damaged. A fouled spark plug will not generate a spark and needs to be replaced. Additionally, check the ignition coil and ensure it has no cracks or signs of damage.

A faulty ignition coil will not send the electric spark to the spark plug, which will prevent the engine from starting. By inspecting the ignition system, you can identify and solve problems that can cause a flooded generator not to start.

Check Spark Plug

One of the most critical components to inspect in the ignition system is the spark plug. This small but mighty device is integral to starting your engine and keeping it running smoothly. Checking your spark plug can reveal a lot about your engine’s performance and health.

If you notice any signs of wear such as cracks, corrosion, or buildup, it’s time for a replacement. It’s also essential to ensure that the spark plug gap is within the manufacturer’s specifications, or else it could cause misfires or poor fuel economy. By regularly inspecting and replacing your spark plug, you can prevent costly repairs and keep your engine performing at its best.

So, make sure you pay attention to your spark plug and keep your engine firing on all cylinders.

Inspect Ignition Coil

If you drive a car, it’s essential to have a smooth-running ignition system. That’s why inspecting the ignition coil is crucial. The ignition coil is responsible for converting low-voltage electricity into high-voltage energy that ignites your car’s spark plugs.

Over time, the ignition coil may become worn and start to misfire, causing your car to sputter or even stall. Checking the ignition coil is easy; just look for any visible signs of corrosion or damage. If you do find damage, it’s best to replace the coil to ensure your car runs smoothly.

But if you’re not sure what you’re looking for, a professional mechanic can quickly diagnose and repair any issues with your ignition system. By keeping your ignition system in good condition, you’ll be able to enjoy a reliable and smooth driving experience without any hiccups.

Examine Flywheel Key

When it comes to your small engine, checking your ignition system is an important part of maintaining your equipment. One element to pay attention to is the flywheel key. This tiny key, usually made of metal, sits between the flywheel and the crankshaft and is responsible for aligning them properly.

If it becomes sheared or damaged, it can cause the engine’s timing to be off or prevent it from starting altogether. Inspecting the flywheel key should be a routine part of your small engine maintenance plan. To do this, remove the starter assembly and take a close look at the key.

If it appears to be damaged or worn, it should be replaced immediately to prevent any further issues. By giving attention to the small details of your engine’s ignition system, you can ensure that your equipment is running at its best.

Assess the Air Intake System

When dealing with a flooded generator that won’t start, the air intake system should be assessed carefully. This system is responsible for supplying air to the combustion chamber, where the fuel is burned to produce energy. If the air intake system is clogged or damaged, the generator won’t be able to receive enough air, which will result in poor performance or prevent it from starting entirely.

One way to check the air intake system is to remove the air filter and inspect its condition. If it’s dirty or clogged, it should be cleaned or replaced. Additionally, check for any obstructions in the air intake ducts or any damage that may be causing air leaks.

By ensuring that the air intake system is functioning correctly, the generator should be able to receive enough air to start and run efficiently.

Inspect Air Filter

Taking care of your car’s air intake system is important for ensuring optimal engine performance and longevity. One crucial component of this system is the air filter, which prevents dust and debris from entering the engine. It’s essential to inspect the air filter regularly, typically every 12,000 to 15,000 miles or when you notice a decrease in engine power.

Neglecting the air filter could lead to reduced acceleration, increased fuel consumption, and potential engine damage, which could cost you a significant amount of money. It’s easy to inspect the air filter yourself by locating it under the hood, removing it from its holder, and checking for any visible dirt, dust, or debris. If you notice that your air filter is dirty, it’s time to replace it with a new one.

Maintaining your air intake system regularly is essential, and ensuring your air filter is in good condition is a crucial part of staying on top of your car’s maintenance.

Check Valves and Compression

When assessing the air intake system, it is essential to check for check valves and compression. A check valve is a type of valve that only allows air to flow in one direction and prevents any backflow. Often, the engine requires air to flow in only one direction, and a check valve ensures that the air flows in that direction.

On the other hand, compression is significant in the air intake system as it ensures that the air entering the engine is at the correct pressure. If the air pressure is too low, it can negatively affect the engine’s performance. Therefore, it is necessary to check the compression and ensure that it is at the appropriate level.

By having functioning check valves and maintaining the proper compression, the air intake system can operate efficiently, ensuring the engine performs at its best.

Preventative Measures to Avoid Future Flooding

One of the most common issues during flooding is a flooded generator that won’t start. To avoid this problem in the future, homeowners can take preventative measures such as elevating their generator and ensuring it is properly anchored. It’s also important to have a regular maintenance schedule for the generator, checking and changing the oil and filter as needed.

Additionally, investing in a backup power source such as a solar generator or battery backup system can provide peace of mind during power outages caused by floods. By taking these simple steps, homeowners can avoid the frustration and expense of a flooded generator that won’t start when they need it most.

Conclusion

Even a generator wants to avoid getting their feet wet! When flooded from excess water, it’s no surprise that it won’t start. Just like how we avoid swimming with a stomach full of food, generators avoid running with a full tank of water. So, keep those flood pants on and don’t let your generator get saturated.

Stay dry and your power will too!”

FAQs

What are some common causes of a flooded generator that won’t start?

Some common causes of a flooded generator include over-priming, a clogged air filter, or an issue with the carburetor.

How can I fix a flooded generator that won’t start?

To fix a flooded generator, you can try leaving it to sit for a few hours to allow the excess fuel to evaporate, or you can remove the spark plug and let the cylinder dry out. You may also need to check and clean the air filter, and adjust the carburetor if necessary.

How can I prevent my generator from getting flooded in the first place?

To prevent your generator from getting flooded, you should avoid over-priming it and make sure to regularly clean or replace the air filter. You can also try using a fuel stabilizer to keep the fuel fresh and prevent any buildup in the carburetor.

What should I do if my generator still won’t start after addressing the flooding issue?

If your generator still won’t start after addressing the flooding issue, you may need to check the spark plug, fuel lines, and fuel filter for any issues. It’s also possible that there may be a deeper mechanical issue that requires a professional’s assistance.